Why This Comparison Matters for Agro-Industries

Agro-processing plants and rural industries generate huge volumes of residues: husk, shells, stalks, straw, peels, spent wash and kitchen waste. At the same time, many facilities rely on expensive fuels like diesel, LPG and furnace oil for boilers, dryers, furnaces, gensets and process heat.

The opportunity is clear: convert residues into useful energy or products. But the correct pathway depends on the residue type (dry vs wet), the final goal (power/heat vs gas vs carbon products), and your ability to operate and maintain the system. This guide helps you choose with real-world constraints in mind.

Three Pathways at a Glance

Biomass Gasification

A thermochemical process that converts dry biomass into syngas (producer gas) for power generation or thermal heat.

Biogas (Anaerobic Digestion)

A biological process where microbes break down wet organic matter to produce methane-rich biogas and nutrient-rich digestate.

Pyrolysis

Thermal decomposition of biomass without oxygen to produce biochar and bio-oil, with strong potential for carbon value.

1. Biomass Gasification (Efficiency-Focused Technology)

Biomass gasification is a thermochemical process that converts solid organic matter into syngas (producer gas). Unlike direct burning, gasification occurs in a controlled, low-oxygen environment, improving conversion efficiency and enabling cleaner, more controllable energy use.

Best For

- Industries with dry residues (typically moisture below 20%): rice husk, cotton stalks, maize cobs, coconut shells, wood chips.

- Sites needing reliable thermal heat or electricity for continuous operations.

The Technology

Enersol’s ESB-R Series Gasifiers are designed for portability and field-friendly operation with dry filtration. Unlike wet scrubber-based systems, this approach reduces water consumption and avoids the need for a large water treatment setup.

Primary Outputs

- Electricity: powering irrigation pumps or replacing diesel generator (DG) sets.

- Thermal Heat: replacing LPG/diesel in boilers, dryers (tea/spices) and furnaces.

ROI Factor

Replacing a diesel engine or DG set with an ESB-R unit can typically save a major share of fuel cost in suitable conditions. Many projects target payback in the 18 to 24 month range, depending on run-hours, residue cost and the displaced fuel price.

Explore Enersol Biomass Gasifiers

Learn more about our gasifier models and applications for agro-industries, boilers, dryers and power.

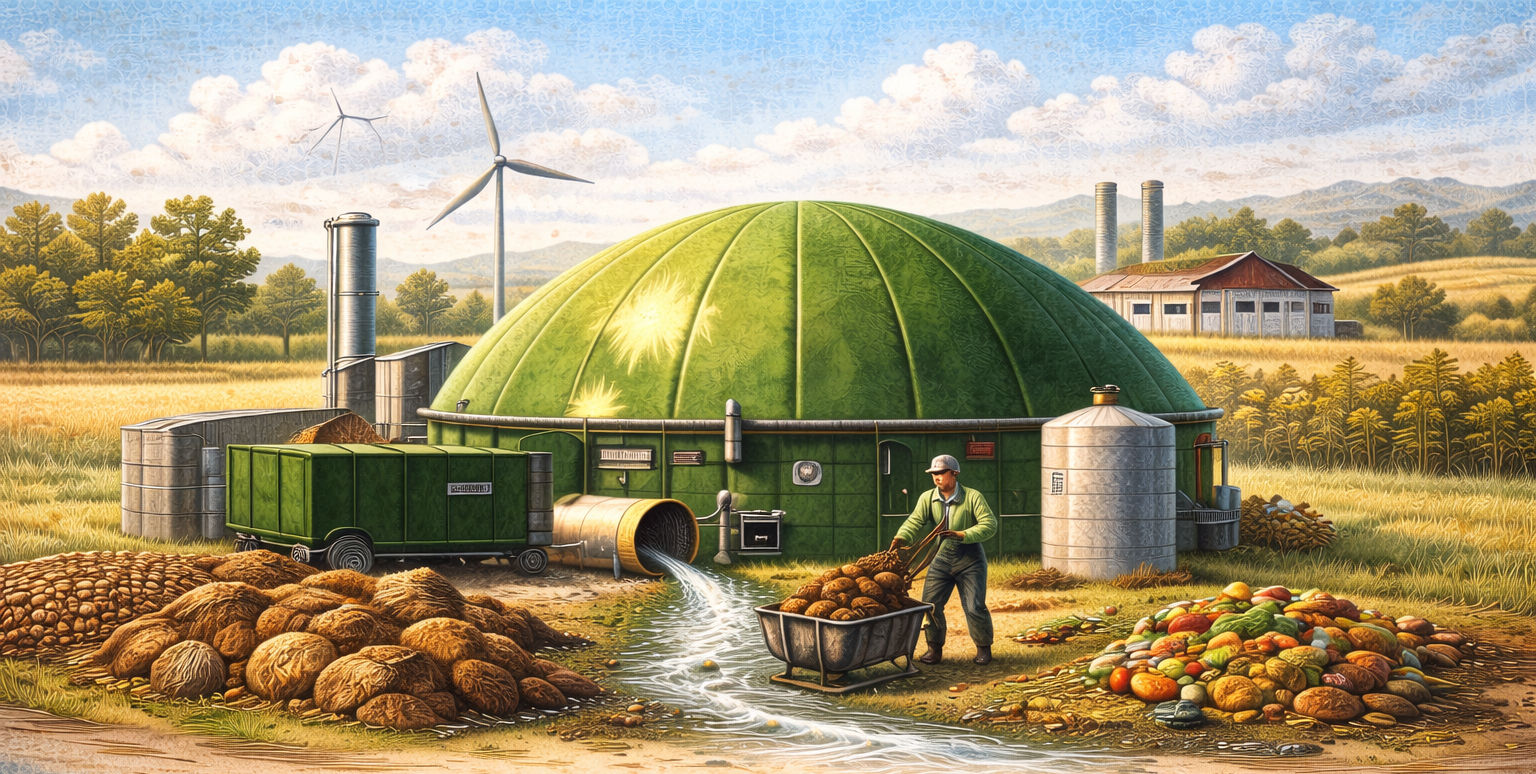

2. Biogas (The Circular Bio-Economy)

Biogas uses anaerobic digestion (AD), where microorganisms break down organic matter in the absence of oxygen to generate methane-rich biogas. It is especially powerful for agro-industries because it solves two problems at once: waste treatment and energy generation.

Best For

- Wet or green waste (moisture up to ~95%): cattle dung (gobar), food waste, distillery spent wash, fruit/vegetable peels.

- Facilities where waste disposal costs are high and consistent feedstock is available daily.

The Technology

Enersol provides CSTR (Continuous Stirred Tank Reactor) plants and Biogas Gensets (2kVA to 100kW) designed for stable operation and predictable output when managed correctly.

Primary Outputs

- Biogas: clean flame for industrial kitchens or steady power generation.

- Digestate: nutrient-rich fertilizer that can be sold or reused in fields.

ROI Factor

Biogas is ideal where your waste stream is guaranteed and disposal is expensive. The combined value from energy savings plus digestate fertilizer often supports ROI expectations in the 3 to 5 year range, depending on site scale and operations.

Explore Enersol Biogas Gensets

See how our biogas gensets and AD solutions can convert wet waste into steady power and usable gas.

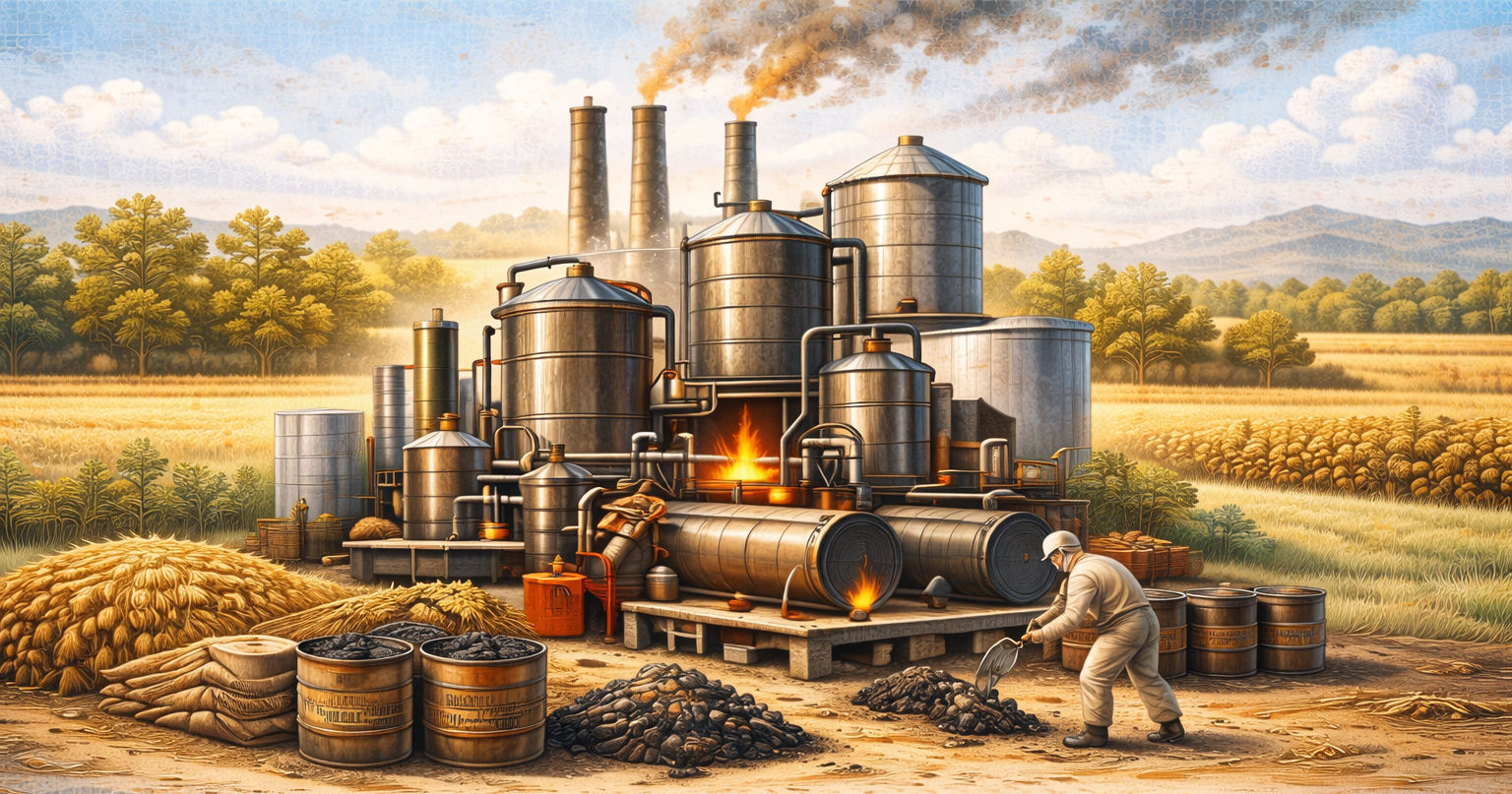

3. Pyrolysis (The Carbon Sequestration Expert)

Pyrolysis is the thermal decomposition of biomass at high temperatures (typically 300°C to 600°C) in the complete absence of oxygen. Instead of releasing most carbon as CO2 (as in open burning), a large fraction can be captured in solid form as biochar.

Best For

- High-carbon residues like rice straw, wheat straw and woody stalks.

- Facilities targeting soil improvement, biochar markets or long-term carbon value.

The Technology

Our Biochar Pyrolysis Plants focus on carbon locking. This is especially relevant as carbon accounting frameworks evolve and high-quality biochar projects gain attention.

Primary Outputs

- Biochar: soil conditioner that improves water/nutrient retention and can persist for long periods.

- Bio-oil (pyrolytic oil): liquid fuel used in industrial burners (application-dependent).

ROI Factor

Pyrolysis economics can be improved by combining product value (biochar + bio-oil) with emerging opportunities from carbon credit and carbon removal markets. In many projects, this creates a third revenue stream beyond fuel savings.

Explore Enersol Pyrolysis Plants

Learn how our pyrolysis solutions can help convert straw and stalk residues into biochar and value.

Summary Comparison Table

| Feature | Biomass (Gasification) | Biogas (AD) | Pyrolysis |

|---|---|---|---|

| Enersol Model | ESB-R Series (5kW-300kW) | Biogas Genset Systems | Biochar Pyrolysis Plant |

| Input State | Dry, solid residue | Wet organic waste | Dry, high-carbon residue |

| Process Type | Thermochemical (partial O2) | Biological (no O2) | Thermal (no O2) |

| Primary Goal | Direct power and/or process heat | Cooking gas, power and fertilizer | Carbon locking and bio-oil output |

| Key Advantage | Compact, portable; strong fuel savings | Closes the nutrient loop via digestate | Supports carbon credit / removal value |

Best Use Cases and Selection Tips

Choose Gasification When

- Your waste is dry and abundant (husk, shells, chips, stalks).

- You need predictable heat/power and want to replace diesel/LPG.

- Run-hours are high (better economics for gensets and thermal systems).

Choose Biogas When

- Your waste is wet (dung, peels, spent wash, food waste).

- You can ensure daily feedstock supply and operational discipline.

- Digestate value or waste disposal savings improve ROI.

Choose Pyrolysis When

- You have straw/stalk residues and want to avoid open burning.

- Biochar markets or soil improvement benefits are relevant.

- Carbon credit potential is part of your project strategy.

A Practical Rule of Thumb

Dry waste typically points to gasification for direct energy. Wet waste typically points to biogas for circular value (energy + fertilizer). Straw and high-carbon residues often favor pyrolysis when long-term soil and carbon benefits matter.

Why Choose Enersol Biopower?

Founded by Mr. Rai Singh Dahiya , a National Innovation Award winner, Enersol Biopower is a pioneer in small-scale, decentralized bioenergy for rural and industrial applications.

- Zero Water Waste: our dry-filtration gasifiers are designed to reduce water handling and wastewater challenges.

- Versatility: fuel-agnostic engineering that can handle multiple agro-residue types (within specification).

- Proven Record: 70+ successful installations across India and global markets.

Whether you are planning a power plant, process-heat system, waste-to-energy unit or a carbon-value biochar project, our team can help with system sizing, fuel analysis, integration and on-site commissioning.

Conclusion: Ready to Turn Your Waste into Wealth?

The best technology depends entirely on your residue stream and your energy goals. If your waste is dry and you need direct power/heat, gasification is often the most straightforward route. If your waste is wet and continuous, biogas can close the loop with energy plus fertilizer. If you want long-term soil and carbon value from straw-like residues, pyrolysis can unlock biochar and emerging carbon opportunities.

Share your feedstock details, energy loads (heat/power), operating hours and budget. Enersol Biopower can help you shortlist the right pathway and design a system that is technically sound, maintainable and ROI-driven.

Need a Techno-Economic Recommendation for Your Agro-Industry?

Enersol Biopower designs and supplies biomass gasifiers, biogas systems, and pyrolysis solutions for agro-industries. Share your waste type and energy needs, and our technical team will recommend the most suitable technology mix.

Contact Our Technical Team